Parts and Components :

overhead crane, jib crane, gantry crane and KBK project

- Electric chain Hoist

- Electric wire rope hoist

- Electric/ manal trolley

- Motor

- Wheel block

- Electrical components

- Rail and track

- Pendant control/remote control

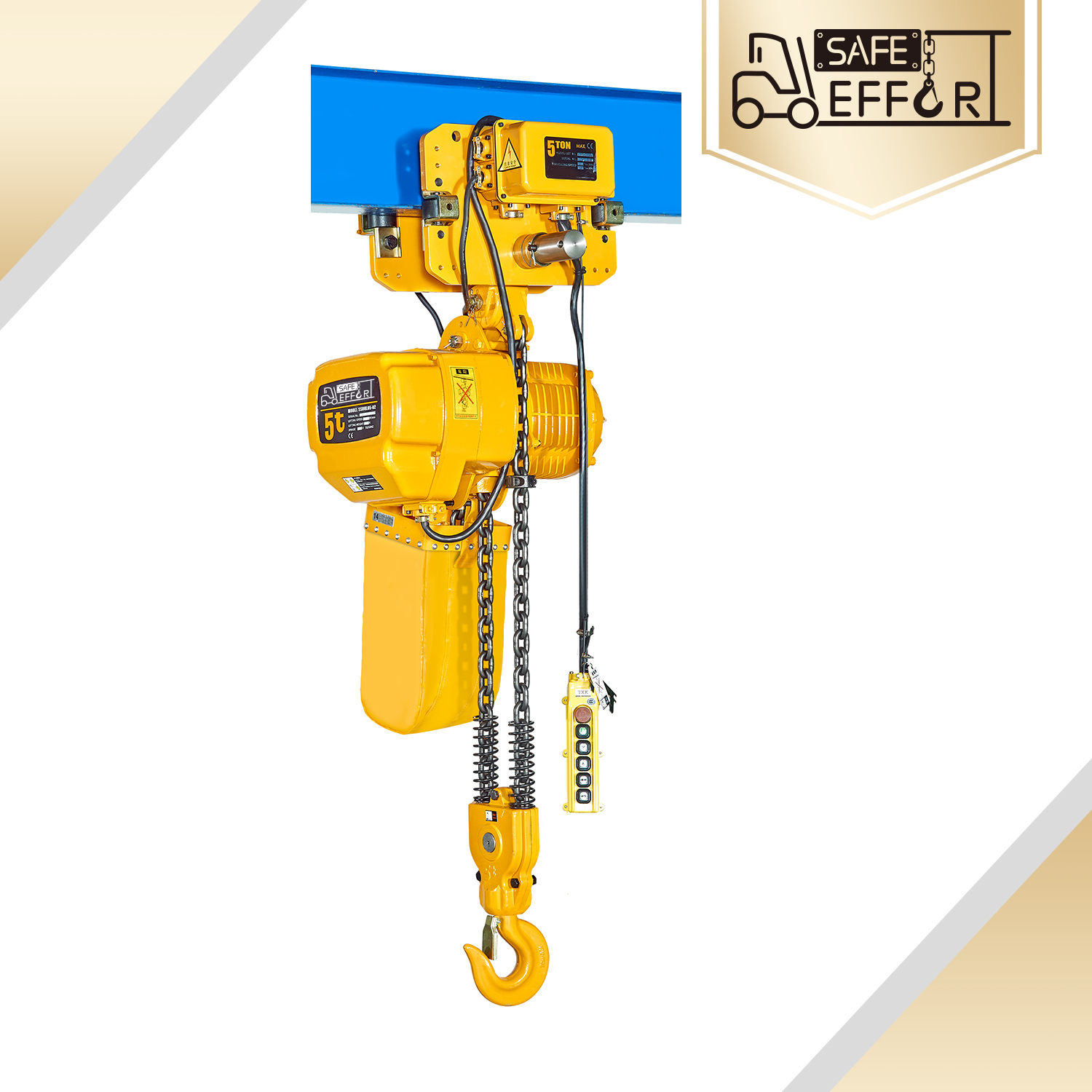

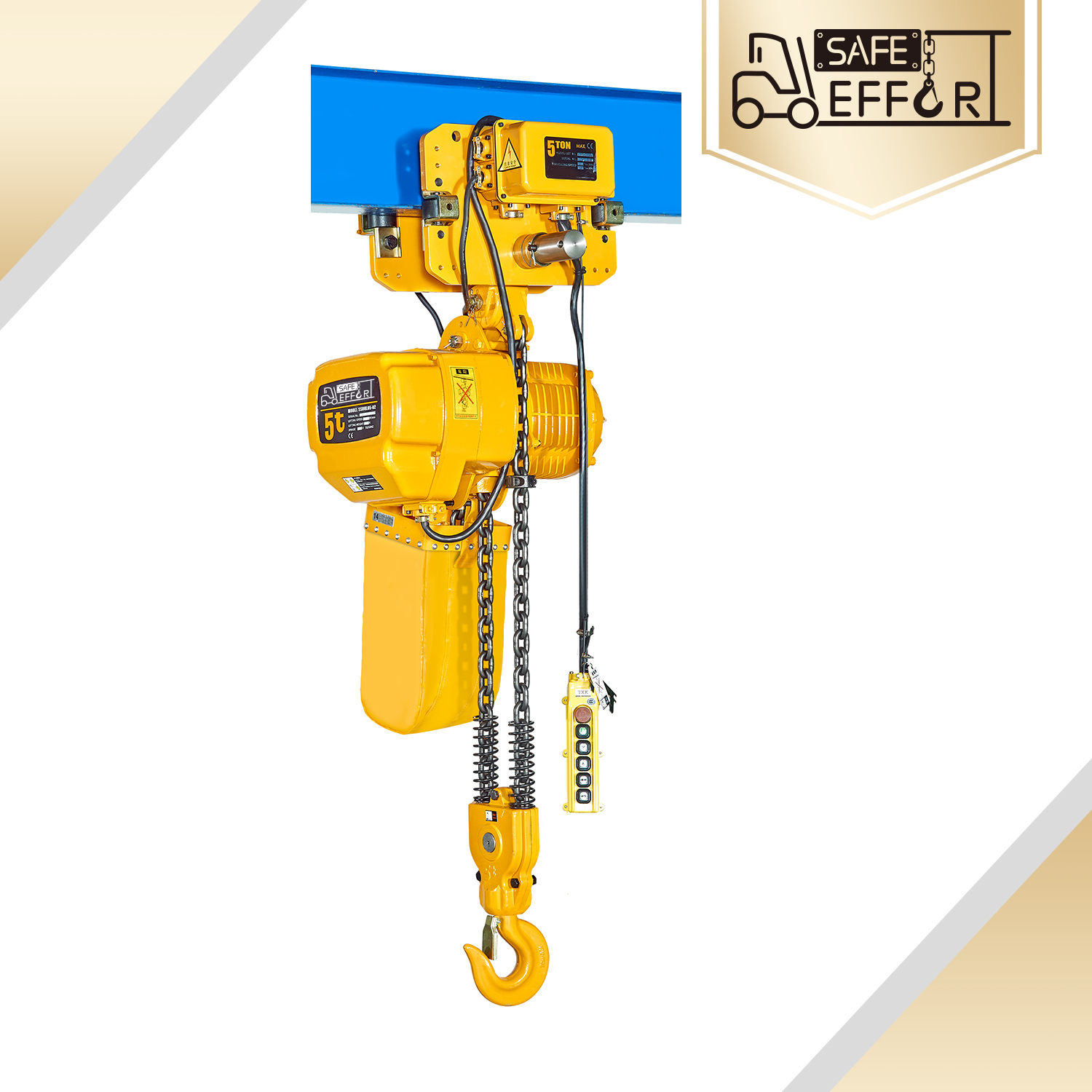

SE series electric chain hoists are equipped with dual lifting and moving speed, which are made of high-strength alloy, consists of beautiful appearance, compact mechanism, small in size and light weight. Besides we use double-geared drive, helical gear drive when it works under fast speed, so that the hoists can drive smoothly with low noise

● Capacities from 250kg to 50 ton are available

● Side magnetic braking device allows instant brake as soon as the electric power cut off

● Upper and lower electrical limit switches are installed to prohibit the chains from exceeding for safety.

● Inverse phase sequence protecting device is special electrical installation which control the circuit not to work in case of wiring error in the power supply

● High quality G80 chain supplied or other imported chains

● Lower hook is ensured by its 360 °rotation and safety tongue piece

● Transformer: 24v,36v,48v transformer device,which is used to prohibit unexpected accidents caused by electric leakage and guarantee the safe use while raining.

● Waterproof push button is applied, which is light and durable

● IP 54/ IP55, M4, F grade

● The length of 3M load chain is standard. Longer length are available (3m to 130m)

● All hoists are CE/ISO certified and comes with instruction manual and Test Certificate.

● Our single phase hoist from 250kg to 1 ton can be manufactured by single phase motor.

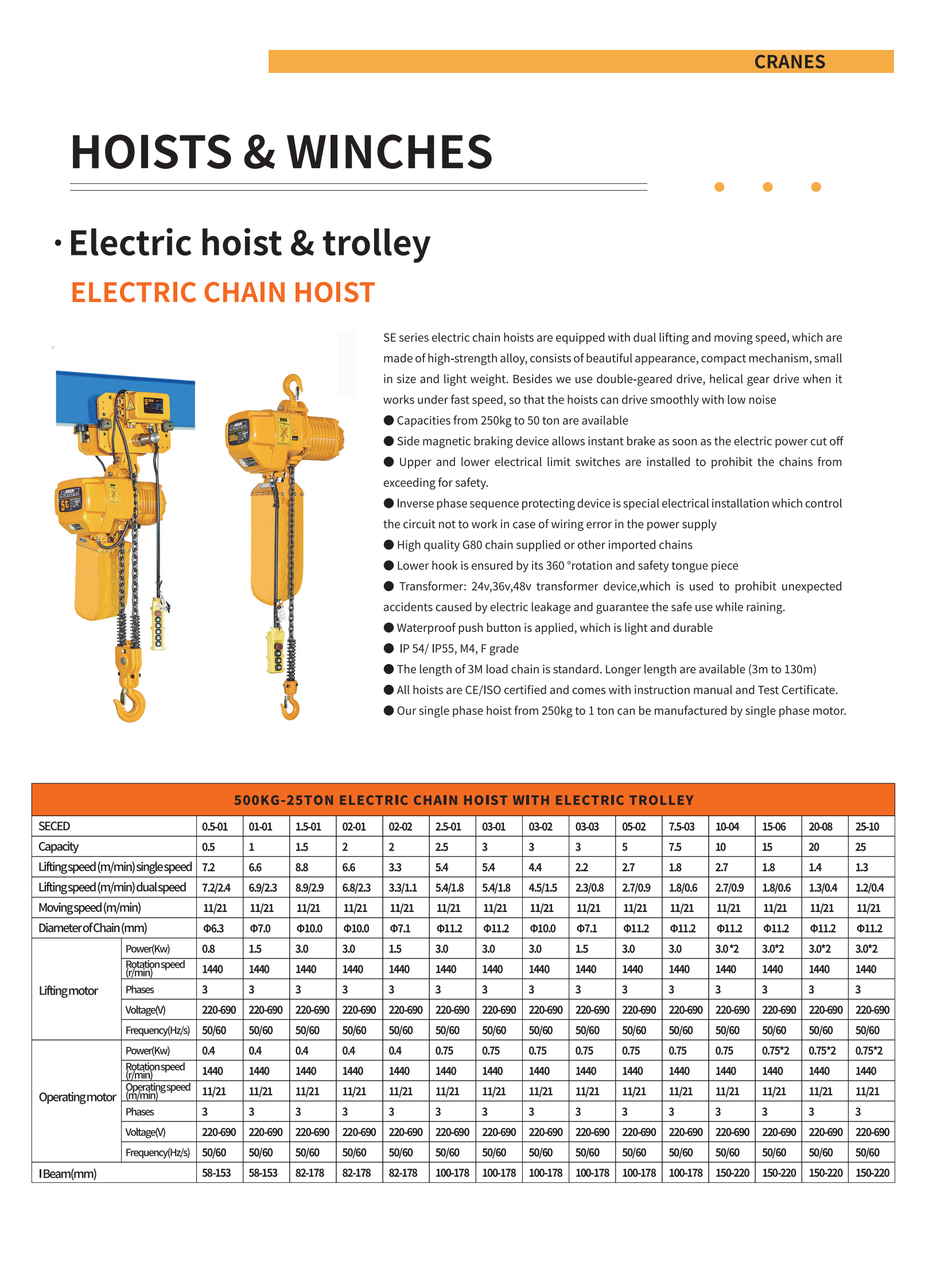

| 500kg-25ton Electric Chain Hoist with Electric Trolley | ||||||||||||||||

| SECED | 0.5-01 | 01-01 | 1.5-01 | 02-01 | 02-02 | 2.5-01 | 03-01 | 03-02 | 03-03 | 05-02 | 7.5-03 | 10-04 | 15-06 | 20-08 | 25-10 | |

| Capacity | 0.5 | 1 | 1.5 | 2 | 2 | 2.5 | 3 | 3 | 3 | 5 | 7.5 | 10 | 15 | 20 | 25 | |

| Lifting speed (m/min) single speed | 7.2 | 6.6 | 8.8 | 6.6 | 3.3 | 5.4 | 5.4 | 4.4 | 2.2 | 2.7 | 1.8 | 2.7 | 1.8 | 1.4 | 1.3 | |

| Lifting speed (m/min) dual speed | 7.2/2.4 | 6.9/2.3 | 8.9/2.9 | 6.8/2.3 | 3.3/1.1 | 5.4/1.8 | 5.4/1.8 | 4.5/1.5 | 2.3/0.8 | 2.7/0.9 | 1.8/0.6 | 2.7/0.9 | 1.8/0.6 | 1.3/0.4 | 1.2/0.4 | |

| Moving speed (m/min) | 11/21 | 11/21 | 11/21 | 11/21 | 11/21 | 11/21 | 11/21 | 11/21 | 11/21 | 11/21 | 11/21 | 11/21 | 11/21 | 11/21 | 11/21 | |

| Diameter of Chain (mm) | Φ6.3 | Φ7.0 | Φ10.0 | Φ10.0 | Φ7.1 | Φ11.2 | Φ11.2 | Φ10.0 | Φ7.1 | Φ11.2 | Φ11.2 | Φ11.2 | Φ11.2 | Φ11.2 | Φ11.2 | |

| Lifting motor | Power(Kw) | 0.8 | 1.5 | 3.0 | 3.0 | 1.5 | 3.0 | 3.0 | 3.0 | 1.5 | 3.0 | 3.0 | 3.0 *2 | 3.0*2 | 3.0*2 | 3.0*2 |

| Rotation speed(r/min) | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | |

| Phases | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | |

| Voltage(V) | 220-690 | 220-690 | 220-690 | 220-690 | 220-690 | 220-690 | 220-690 | 220-690 | 220-690 | 220-690 | 220-690 | 220-690 | 220-690 | 220-690 | 220-690 | |

| Frequency(Hz/s) | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 | |

| Operating motor | Power(Kw) | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75*2 | 0.75*2 | 0.75*2 |

| Rotation speed(r/min) | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | 1440 | |

| Operating speed(m/min) | 11/21 | 11/21 | 11/21 | 11/21 | 11/21 | 11/21 | 11/21 | 11/21 | 11/21 | 11/21 | 11/21 | 11/21 | 11/21 | 11/21 | 11/21 | |

| Phases | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | |

| Voltage(V) | 220-690 | 220-690 | 220-690 | 220-690 | 220-690 | 220-690 | 220-690 | 220-690 | 220-690 | 220-690 | 220-690 | 220-690 | 220-690 | 220-690 | 220-690 | |

| Frequency(Hz/s) | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 | |

| I Beam(mm) | 58-153 | 58-153 | 82-178 | 82-178 | 82-178 | 100-178 | 100-178 | 100-178 | 100-178 | 100-178 | 100-178 | 150-220 | 150-220 | 150-220 | 150-220 | |